ZMLB Asphalt Batching Plant

Review

Description

SPECIFICATIONS FOR IKOM ASPHALT BATCHING PLANT

Model |

ZMLB1000 |

ZMLB1200 |

ZMLB1500 |

Capacity (t/h) |

60- 80 |

72- 96 |

90- 120 |

Mixer(kg/batch) |

1000kg |

1200kg |

1500kg |

Dryer drum |

Φ1650mm x6500mm |

Φ1650mm x6500mm |

Φ1930mm x7000mm |

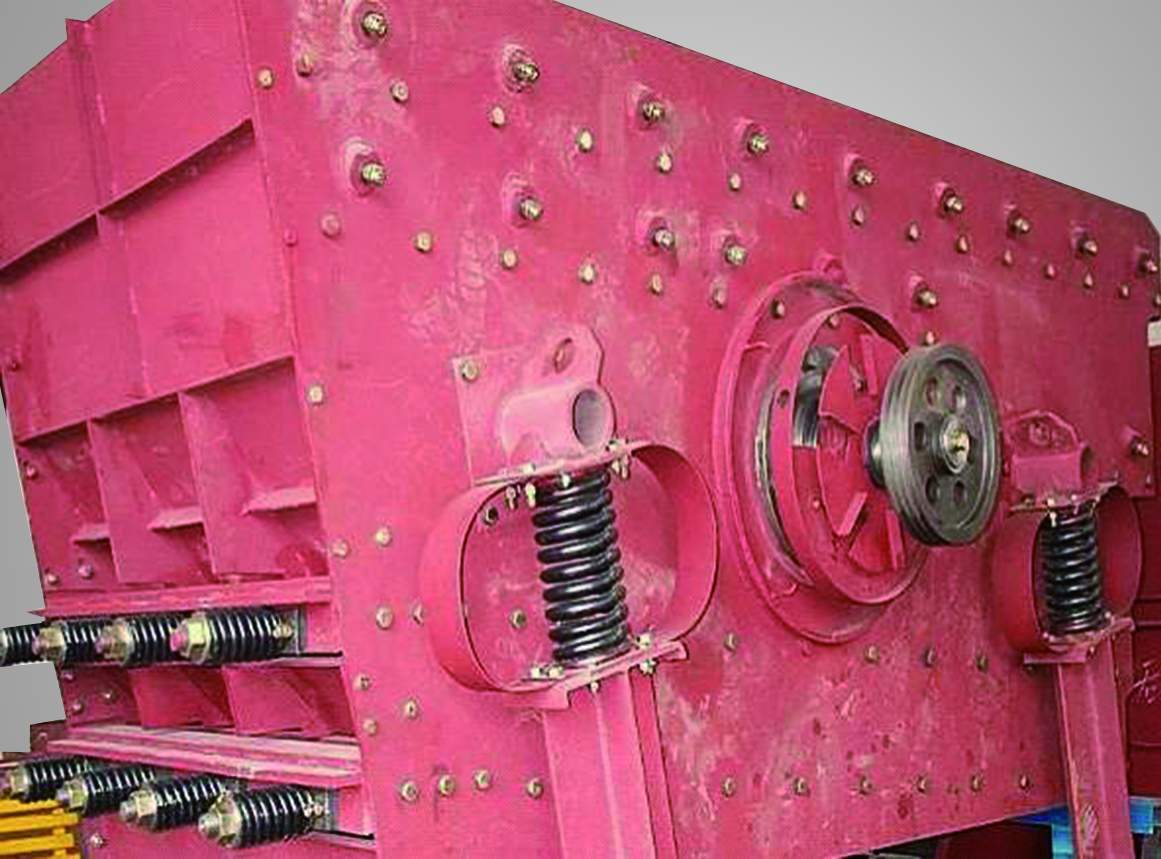

Vibrating screen | 4 layers 4 sizes | ||

Hopper capacity | 8m³ x 4 | ||

Aggregate measuring accuracy | ±0.3% | ||

Filler measuring accuracy | ±0.25% | ||

Bitumen measuring accuracy | ±0.15% | ||

Performance Characteristics

1. Excellent modular integrated design, customized to user needs, fast installation and ease of maintenance or replacement.

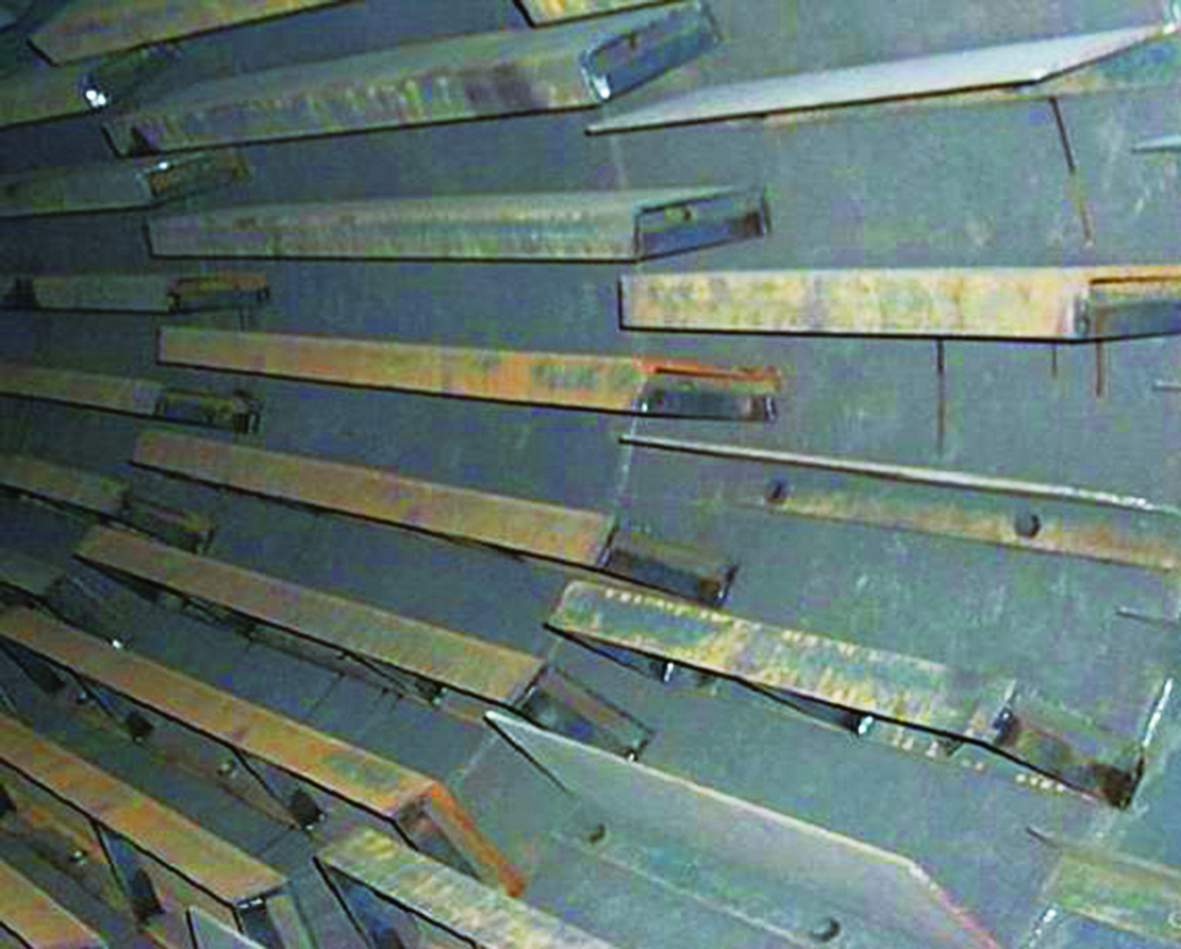

2. Adopting twin-shaft mixer, the mixing is fast and uniform. Auxiliary hydraulic control discharge gate with 3 manual control points make it easy for mixer trucks. Mixing vane and liner boards are of nickel alloy cast iron can be easily replaced.

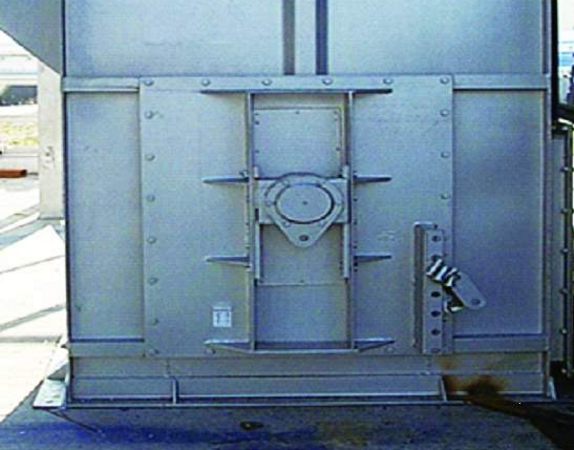

3. Aggregate hoppers desiged with large and small discharge gates to fulfill rough and finee weighting with high precision measurement.

4. Patented pneumatic conveying chute allows rapid material discharge without residue and effectively prevent hardening of cement on the rotating shaft. Compress air are injected into the mixer for a rapid and uniform cement mix.

5. Branded electronic components of high rliability to ensure plant quality outputs.

6. Computerised control system with PLC capable to storing process parameters, auto compensation, manual or auto control setting at any time without affecting other parameters.

7. Production work reports can be printed anytime for review & records.

1. Mixer

2. Cold hopper

3. Drying durm

4. Hot elevator

5. Screening system

6. Filler measure hopper gate